Pump Repair and Refurbishment

Industrial Pump Restoration with Corrocoat Materials – A Solution for Enhanced Performance and Energy Efficiency.

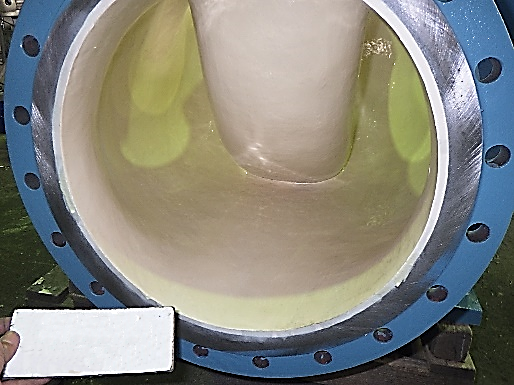

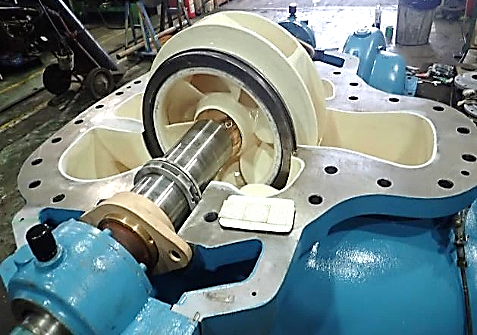

FINE JSC applies specialized materials from Corrocoat to restore the internal surfaces of industrial pumps, particularly areas exposed to erosion, corrosion, and flow loss.

The anti-corrosion polymer coating solution helps reduce friction and offers the following benefits:

-

Optimized flow dynamics within the pump housing, reducing hydraulic losses.

-

Improved operational efficiency, especially for pumps operating in chemical, seawater, or wastewater environments.

-

Significant energy savings by reducing load on the motor.

-

Extended equipment lifespan by minimizing maintenance and replacement costs.

This proven solution is trusted and widely applied in water supply systems, chemical processing, and heavy industrial plants.

Materials used: Corroglass, Fluiglide

Post-restoration and Fluiglide application

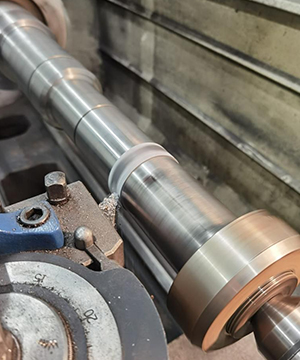

Component Restoration/Replacement

Reassembly

Service includes:

Equipment Inspection & Condition Assessment

- Conduct on-site inspection at the workshop or project site.

- Measure dimensions, evaluate corrosion level, and assess damage.

- Recommend suitable Corrocoat coating materials based on operating conditions (chemicals, seawater, temperature, etc.).

Surface Preparation

- Clean surfaces using grit blasting to meet SA 2.5 standards.

- Inspect surface profile, cleanliness, and adhesion suitability before coating.

- Mask and protect areas not to be coated.

Corrocoat Coating Application

- Mix and apply the coating using brushes, rollers, or spray equipment depending on the type of component.

- Ensure coating thickness meets the technical specifications of each application.

- Monitor environmental conditions (temperature, humidity) to ensure optimal coating performance.

Quality Inspection & Handover

- Test adhesion, thickness, and detect any defects using non-destructive testing (NDT) methods.

- Prepare inspection records and photo documentation before and after restoration.

- Handover and provide operation guidance after curing period.

Benefits of use Pump Repair and Refurbishment

- Exceptional corrosion and erosion protection with specialized coatings from Corrocoat (UK origin).

- Improved equipment performance, restoring the operational efficiency of aged or worn machinery.

- Cost-effective alternative to new investment, extending equipment lifespan.

- Reduced energy consumption, especially for rotating equipment such as pumps and fans.

- Fast and efficient application, ideal for short maintenance windows and scheduled shutdowns.

.png)

.png)