DRIVE SHAFT REPAIR & PROTECTION

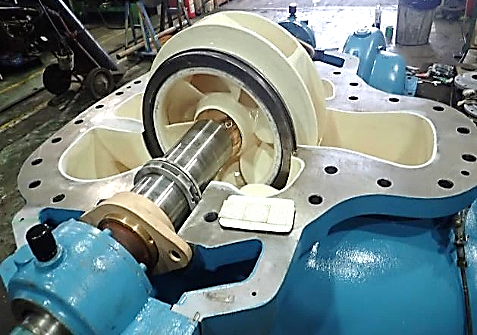

Industrial Drive Shaft Restoration for Heavy Industries.

FINE JSC offers professional restoration and protection solutions for industrial drive shafts using specialized products from Corrocoat – UK, helping to prevent corrosion, mechanical wear, and extend equipment life cycles.

Our services are particularly suited for industries operating in harsh environments such as oil & gas, chemical processing, energy, water treatment, and marine sectors—where drive shafts are subject to continuous wear and severe environmental conditions.

Typical Applications

- Industrial pump shafts

- Turbine shafts, fan shafts, agitator shafts

- Drive shafts for conveyor systems, lifting mechanisms, etc.

Service includes:

Inspection & Damage Assessment

- On-site examination of corrosion, surface pitting, and mechanical wear.

- Identification of root causes and assessment of damage severity to recommend suitable repair plans.

- Preparation of technical reports and proposal of optimized restoration solutions.

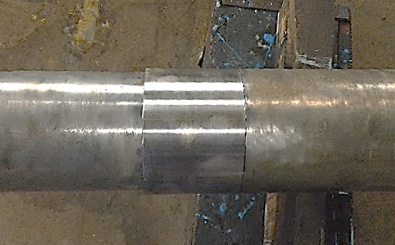

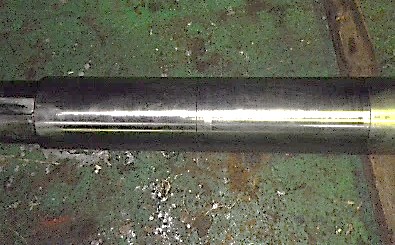

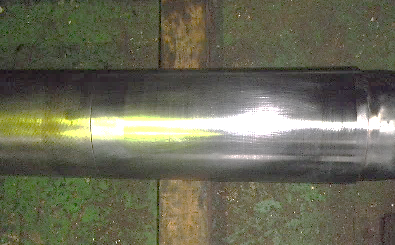

Surface Preparation & Restoration

- Surface cleaning and profiling to meet technical standards.

- Precision repair with composite or filler materials as required.

- Application of Corrocoat anti-corrosion coatings such as Plasmet or Polyglass, tailored to each specific environment.

Quality Control & Handover

- Verification of concentricity, hardness, and adhesion of applied coatings.

- Non-Destructive Testing (NDT) as requested.

- Equipment handover with usage instructions and maintenance guidance.

Benefits of use DRIVE SHAFT REPAIR & PROTECTION

✅ Extended Equipment Lifespan

Corrocoat coatings offer outstanding corrosion resistance, protecting the shaft surface against harsh environments, chemicals, humidity, and mechanical abrasion.

✅ Cost-Effective Solutions

Drive shaft restoration using Corrocoat is significantly more economical than manufacturing or importing new shafts, while also reducing routine maintenance costs.

✅ Minimized Downtime

Fast and flexible restoration procedures help businesses shorten repair time and quickly resume operations.

✅ Improved Operating Efficiency

Restored surfaces are smooth and precisely aligned, reducing vibration and mechanical wear for a more stable and reliable system.

✅ Eco-Friendly

Corrocoat’s polymer-based coatings are free from hazardous substances, reduce waste, and ensure a safe process throughout application and usage.

.png)

.png)