Industrial Pipeline Rehabilitation

Pipeline Rehabilitation Solutions with Corrocoat Technology.

FINE JSC offers rehabilitation services for industrial pipelines damaged by leakage, corrosion, or chemical erosion caused by harsh operating conditions such as seawater, chemicals, and high pressure. Our solutions utilize advanced coating and sealing technologies from Corrocoat – United Kingdom, a global leader in anti-corrosion materials.

Key Advantages

-

On-site Repair: Effectively seals leak points and severely corroded areas using specialized materials without the need to stop equipment or shut down the entire plant.

-

Restoration to Original Condition: Applies internal protective coatings that restore the pipe’s shape and operational performance.

-

Extended Lifespan: Provides resistance against chemical and mechanical corrosion, significantly enhancing the pipe’s durability and operational efficiency.

Applications

-

Water supply, drainage, firefighting, and wastewater treatment systems.

-

Industrial pipelines for chemicals, oil & gas, power plants, and food processing.

-

High-pressure pipelines resistant to temperature, chemicals, and abrasion.

Service includes:

Pipeline Condition Survey & Assessment

- Assess leakage, corrosion, and perforation levels.

- Measure thickness, check pressure resistance, capture technical images.

- Recommend optimized solutions for each damaged location.

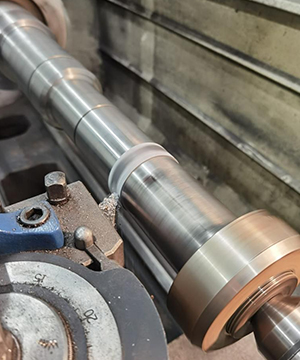

Surface Cleaning & Preparation

- Clean surfaces, remove rust, grease, and contaminants.

- Grit-blast or mechanically clean to achieve SA 2.5 surface preparation standard.

- Inspect surface roughness and adhesion levels.

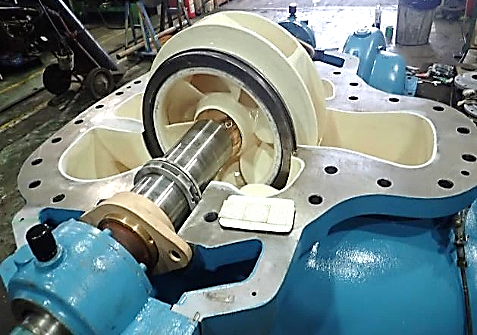

Rehabilitation Application

- Seal leak points using Corrofill and wrap damaged areas with specialized composite materials.

- Apply Corrocoat protective linings to restore internal surface integrity.

- Conduct quality inspection using NDT methods and holiday testing.

Benefits of use Industrial Pipeline Rehabilitation

✅ Prevent and repair corrosion damage

-

Forms a durable barrier against corrosive agents such as chemicals, seawater, acids, alkalis, and other harsh environments.

-

An ideal solution for pipelines suffering from mechanical or electrochemical corrosion in industrial plants.

✅ Extend pipeline system lifespan

-

Enhances resistance to pressure, temperature, and aggressive environments.

-

Minimizes risks of unexpected leaks or failures, reducing unplanned downtime and production interruptions.

✅ Reduce maintenance and replacement costs

-

Significantly more cost-effective than pipeline replacement.

-

Allows for on-site repair without dismantling the system, saving time and minimizing operational disruption.

✅ Flexible application during operation

-

Enables sealing of leaks and corrosion treatment without shutting down the entire plant.

-

Specialized materials are suitable for industries with high standards such as food, pharmaceutical, and water treatment.

✅ Compliant with strict international standards

-

Corrocoat, a UK-based brand, is widely approved and used by global oil & gas, energy, and water treatment corporations.

-

Products like Polyglass VE, Corrofill, Armagel, Plasmet ZF are field-proven across high-pressure systems—both underground and offshore.

.png)

.png)