Polyglass VEF Anti-Corrosion Coating for THIEN UNG 1 Vessel Pipe Spools

FABRICATION INSPECTION AND ENGINEERING JOINT STOCK COMPANY (FINE JSC) is proud to announce the successful completion and handover of a work package involving the application of a high-performance anti-corrosion protection layer, Polyglass VEF, inside the Pipe Spool system for the THIEN UNG 1 Vessel.

This execution clearly demonstrates FINE's capabilities in applying Corrocoat materials and our deep expertise in specialized application techniques, ensuring superior service life for the piping system.

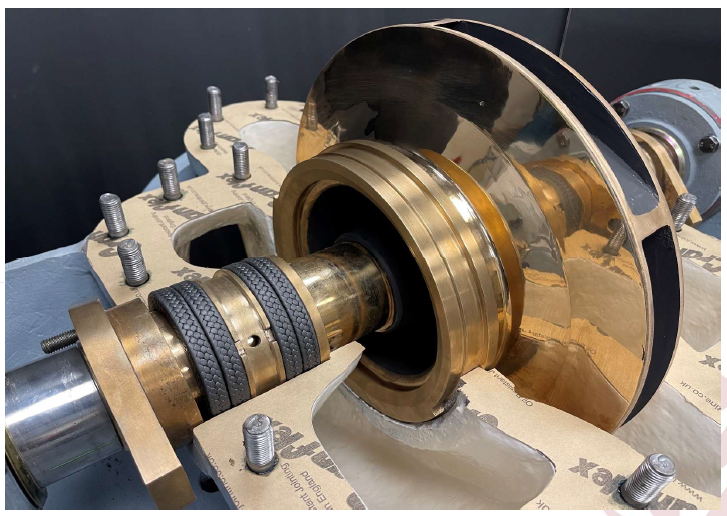

Equipment Condition Before Polyglass Restoration

1. Polyglass VEF: Corrocoat's Standard Anti-Corrosion Material.

FINE utilizes the Polyglass VEF (Vinylester Flake) product from Corrocoat—a world-leading brand. This is a glass flake composite coating system specifically engineered to perform effectively in aggressive environments, such as those involving strong chemicals, solvents, or hot seawater.

-

Superior Protection Mechanism: The overlapping glass flake structure creates a Maximum Permeation Barrier, significantly lengthening the diffusion path for corrosive molecules, thereby preventing Undercutting Corrosion beneath the coating film.

-

Exceptional Durability: Polyglass VEF offers outstanding abrasion resistance and high tolerance to thermal and mechanical variations, resulting in prolonged equipment service life.

Surface Roughness & DFT inspection

2. Specialized Application Techniques & Quality Control (QC).

The quality of the Polyglass VEF coating is 100% guaranteed through strict adherence to Corrocoat's standard application procedures and the expertise of FINE's personnel:

-

Precise Surface Preparation (SA 2.5): Steel grit blasting is performed to achieve a high cleanliness level, with the Surface Roughness (Anchor Profile) carefully measured and maintained to ensure optimal mechanical adhesion.

-

Controlled Application: FINE technicians strictly control the Pot Life (mixing time), ambient conditions (temperature/humidity), and the Dry Film Thickness (DFT), typically between 800-1,000 microns, using specialized equipment.

-

Holiday Detection Inspection: This is the decisive QC step. FINE uses a high-voltage detector to scan the entire surface. The coating is only considered acceptable when no pinholes (discontinuities) are detected, ensuring a completely continuous and protective layer.

-

Quality Documentation: FINE provides comprehensive QC documentation, certifying that every stage complies with Corrocoat application standards and ISO requirements.

3. Conclusion: A Reliable Choice for Industrial Systems.

The successful completion of the Polyglass VEF coating package reaffirms FINE's commitment to Engineering Precision and Premium Application Competence. We are dedicated to providing the most durable asset protection solutions, helping clients optimize efficiency and extend equipment lifespan.

Contact FINE for expert consultation on anti-corrosion coating solutions using Corrocoat’s superior products!

-

Email: info@finejsc.com

-

Hotline: 0826 58 3979

.png)