Anti-corrosion pump by coating Corrocoat - UK

Tuesday, 29/07/2025, 14:53 GMT+7

783 Views

✅ Common conditions:

- Pumps are corroded, worn due to chemicals, seawater, or harsh environments.

- Reduced operating efficiency, leakage, damage to pump impellers, pump chamber.

- The cost of replacing components or new pumps is very high.

✅Our solution:

Using specicalized coating technology Corrocoat-UK, with a special Poly-este and glass flake, capable of:

- Extremely high corrosion and abrasion resistance.

- Creates a thick coating, strong chemical bond with the metal substrate.

- Resists acids, alkalis, solvents and high pressure:

✅ Process:

- Receive and assess pump damage

- Fabrication and restore original shape (if necessary)

- Clean the surface according to SA2.5 standards or higher

- Check the surface with specialized testing tools before painting

- Apply Corrocoat paint (Polyglass, Plasmet, Fluiglide,...)

- Inspect the thick coating and accept

✅Your benefits:

- Save up to 70% of costs compared to replace new pump

- Increase equipment life by 3-5 times

- Reduce downtime, optimize operating costs

- Can be applied to chemical pumps, seawater pumps. mud pumps, vacuum pumps,...

✅ The service has been applied in many power plants, cement, chemicals, oil and gas, petrochemical,...

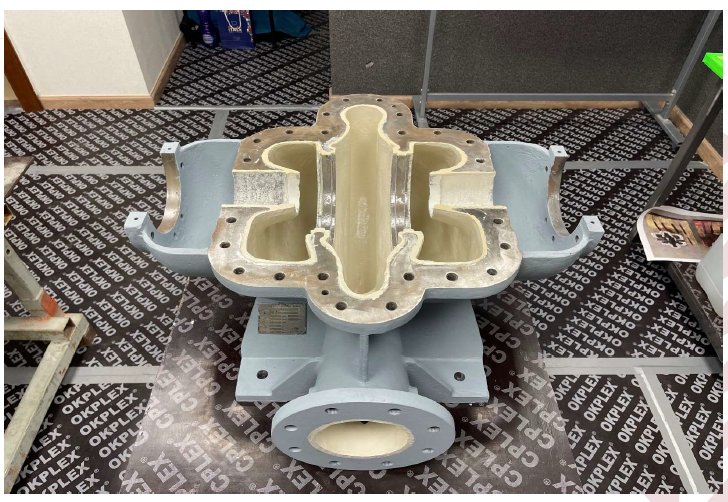

Pump is heavy corroded.

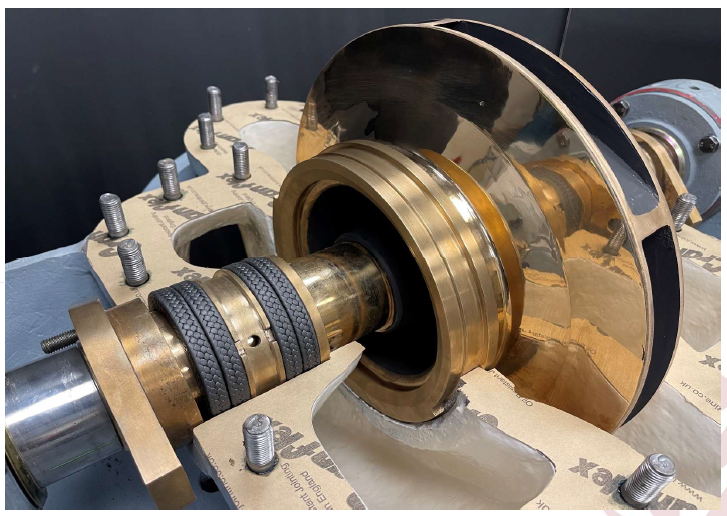

Pump after recovery.

Reader comments

Other Posts

12/11/2025

Engineering quality, precision, and reliability — FINE JSC powering Cambodia’s water development.

05/11/2025

CORROCOAT – Industrial-Grade Corrosion Protection for Critical Infrastructure.

Contact us

We're here to help! Please fill out the form below, and our specialists will get in touch with you shortly to discuss your needs.

.png)